Maintenance is investment

The improvement of the efficient operation of the facilities, and the possibilities to achieve other goals such as life cycle management without exceeding the budgets for their maintenance, depends on a good maintenance programs.

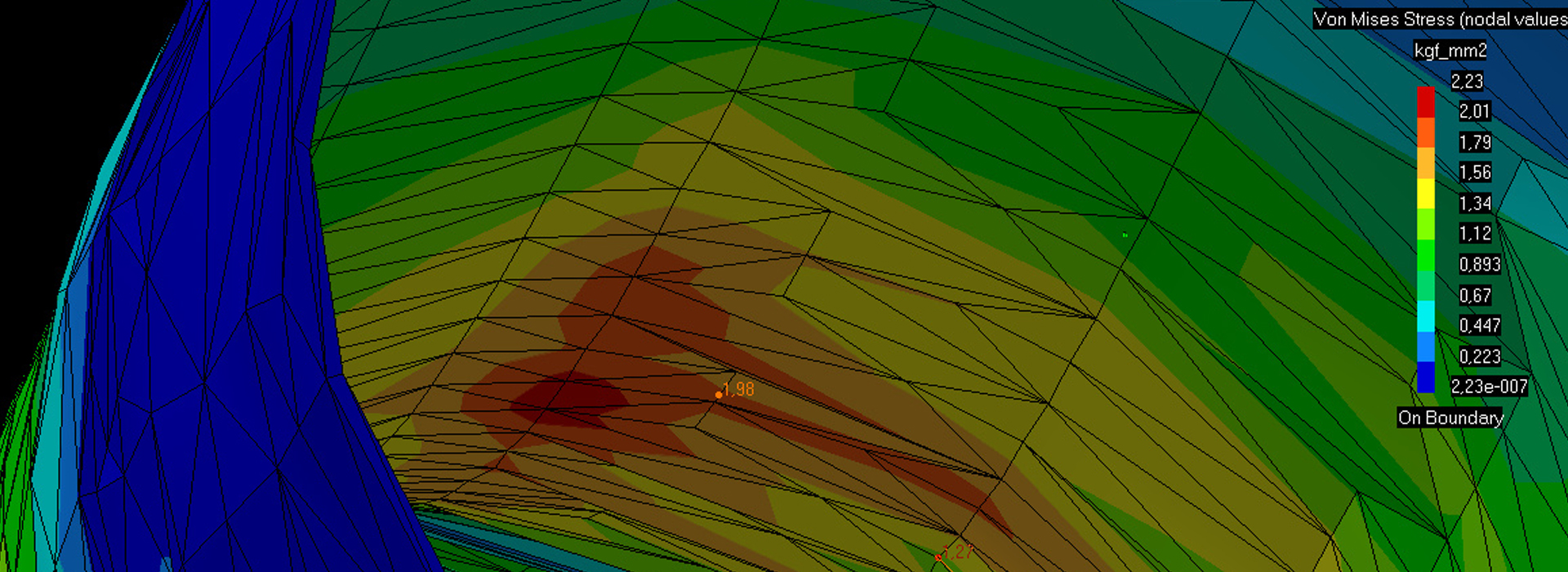

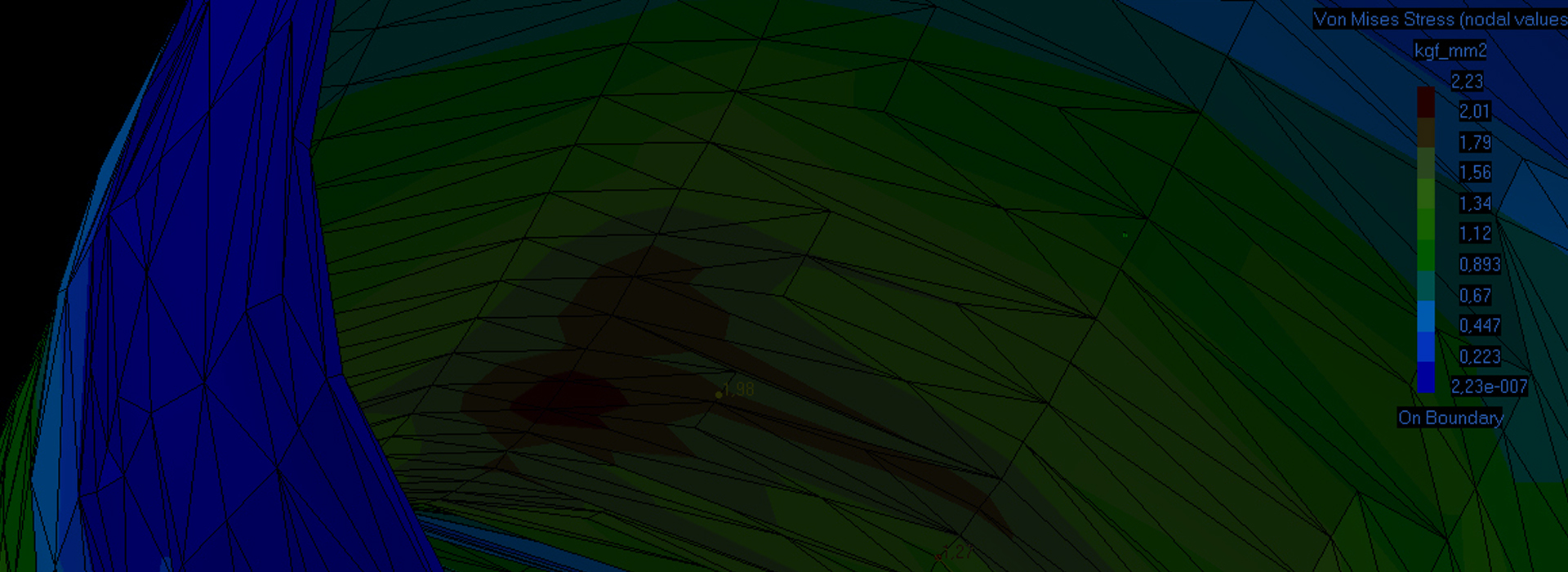

If the measurement and control methods are performed on equipment during normal operation and regular temperatures, we can also guarantee that the actual measurement provides real functioning values, without interfering with the production process.

POLÍTICA DE CALIDAD

R.A. INGENIERIA S.A., establece, su política de calidad, a través de lo expresado en la misión, visión y valores.

Who we are

The founder of our company, engineer Raul Angel Ambrosi, worked since 1968 in the area of maintenance of the cement factory Loma Negra CIASA located in Olavarria, until 1978. This factory had seven kilns and 14 mills running.

From 1979 thru 1980 he was the technical director of the mechanical assembly of the Malagueño factory, in Córdoba, Argentina, for Juan Minetti SA Company, and after the start up, assuming the position of plant director. Since 1983, he dedicated to advise on assemblies in cement, gypsum factories, and cement kilnsaxis alignment as well.

In 2003, he founded R.A. Ingenieria SA, which, to date, has done a lot of works in mining, petrochemical, paper, lime, and especially cement companies.

The company staff, as a whole, has more than sixty years of technical experience in the cement industry, performing comprehensive mechanical diagnostics, repairs, and helping with projects planning for major repairs and to optimize the equipment performance.

All staff of the company had actively participated in the design and assembly of every equipment and software, and developed the methods to achieve the best service and accuracy. That is why we know what we do, why we do it and how we do it.

Filosofía

Podemos afirmar sin equívocos que las políticas de puertas abiertas y trabajo en equipo de nuestra empresa, ha permitido el alto nivel de desarrollo de los procedimientos, equipos, y personal. Todo el personal de esta compañía participó activamente en el diseño, armado de equipos y máquinas, software, y la preparación de procesos y métodos para llevar a cabo las tareas. Es por esto que sabemos qué hacemos, porqué lo hacemos y cómo hacerlo.

Queremos lograr una relación estable y duradera con nuestro cliente, por ello creamos una estrecha relación con ellos. La organización de nuestros equipos técnicos permite que sea un mismo grupo el que participa en todo el proceso del servicio. De esta manera conocen perfectamente el cliente, y todos los detalles de los servicios prestados.

Nuestro personal es altamente calificado y poseen know how acorde al servicio prestado.

Creemos que al cumplir nuestros compromisos honramos la confianza que nuestros clientes nos tienen, el respeto y la cordialidad, son valores que apreciamos y ponemos al servicio de nuestros clientes.

Mission

To perform calculations and related designs and mechanical mounts and repairs on equipment and facilities.

To provide our services with the highest quality, accuracy and security.

Vision

Nuestros Valores

Compromiso: por el trabajo bien realizado y confiabilidad de los procesos, orientados hacia la mejora continua. Promovemos la interacción, el esfuerzo y la contribución de todo nuestro personal hacia el logro de los resultados y la satisfacción de nuestros clientes.

Respeto: cuidamos nuestros vínculos con todas las partes interesadas, atendiendo con eficiencia, cortesía y espíritu de servicio los requerimientos que nos sean solicitados, atendiendo los mismos con calidez y cercanía cada uno de ellos.

Confianza: construimos relaciones basadas en la consideración personal y profesional, brindamos respaldo y seguridad a nuestros clientes, y a nuestro personal. Poseemos alta competencia técnica.

Permanente actitud de servicio: brindamos a nuestros clientes total apoyo y compromiso en la consecución de sus objetivos. Fomentamos y ejercemos el trato personalizado y activo entre nuestro personal y nuestros clientes.

Seguridad Operativa. La seguridad no se negocia.

Objetivos de calidad

R.A. INGENIERÍA S.A. asegura que los objetivos de la Calidad se establezcan en todos los procesos comprendidos en su Sistema de Gestión de Calidad, siendo éstos mensurables y acordes a los requerimientos propios de sus servicios y a la política de la calidad de la empresa. Los objetivos de la calidad son considerados registros de la calidad y sometidos también al proceso de mejora continua.